Product Description

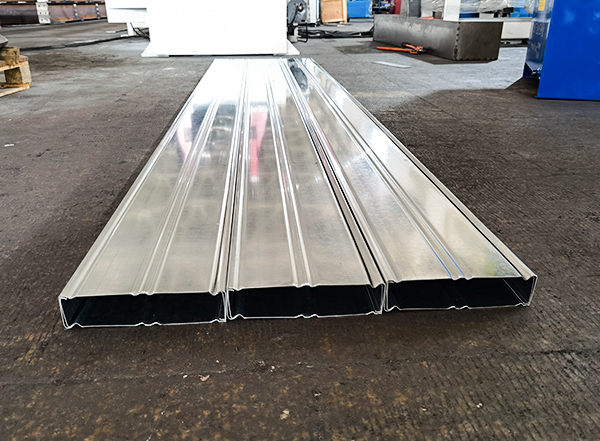

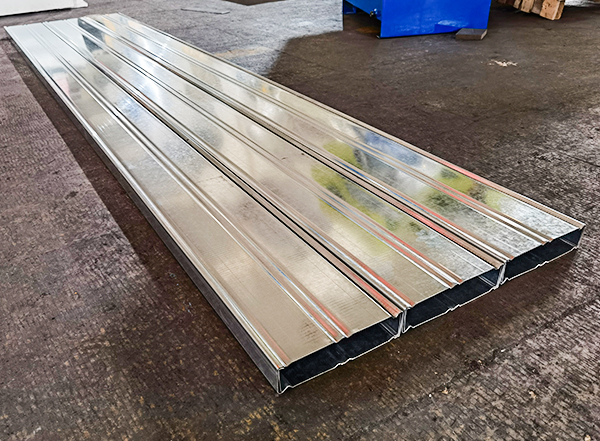

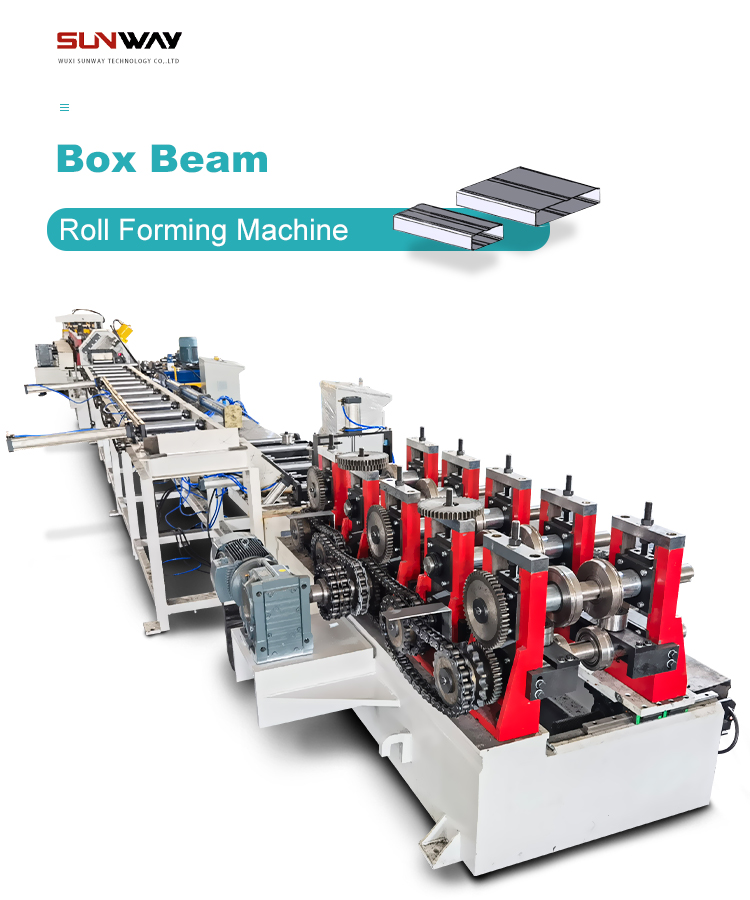

Box beam roll forming machine is developed to produce the beam which is fixed

between the upright racks. It normally have two types: 1) both C beams are roll formed

on a roll forming machine then seamed in a combined roll former to get a box beam;

2) one beam is formed on a roll forming machine directly to get a box beam.

Our intelligent roll forming machine could make various sizes of beam with thickness

Our intelligent roll forming machine could make various sizes of beam with thickness

1.5-3.0mm. Uncoiling, feeding, roll forming, welding, cutting etc process can be

automatically realized on one line. Meantime, we have the roll forming machine to make

step beam, upright rack and shelf panels. All these are components of Pallet racking

system.

In warehouse pallet racking system, we are able to manufacture more machines like

In warehouse pallet racking system, we are able to manufacture more machines like

Step beam roll forming machine, Upright rack roll forming machine and shelf panel

(box plate) roll forming machine etc.

We make different solutions according to customers’ drawing, tolerance and budget,

We make different solutions according to customers’ drawing, tolerance and budget,

offering professional one-to-one service, adaptable for your all requirements. Whichever

line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly

functional profiles.

Profile Drawings

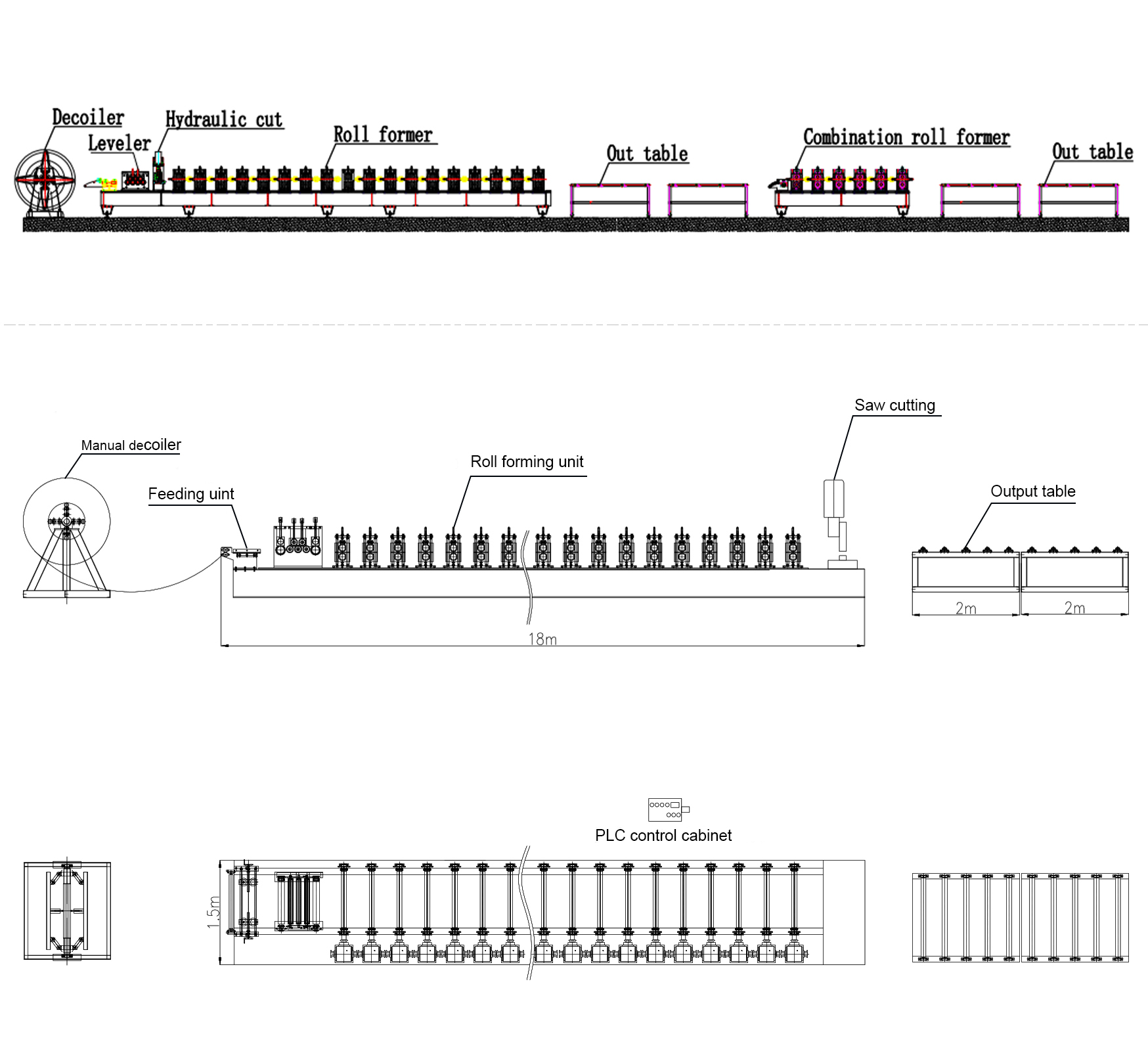

Production Line

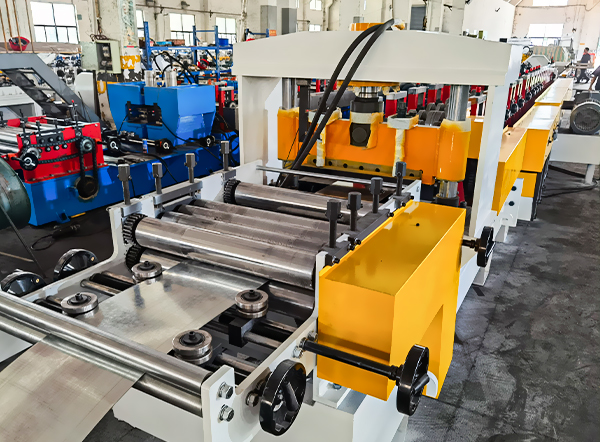

Product Details

Manual Decoiler Hydraulic Decoiler (Optional)

Hydraulic Pre-cutter Hydraulic Post Cutter

Saw Cutter Seaming Roll Former

Box Beam Roll Forming Machine Split Type: Roll Forming + Seaming

(Combined Type)

(Combined Type)

Product Paramenters

|

|

||

|

|

|

|

|

|

||

|

|

||

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

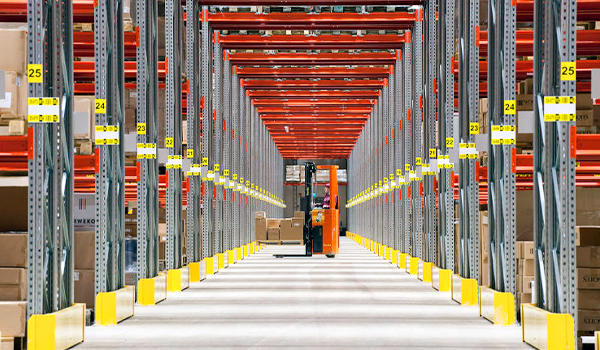

Application

Reviews

There are no reviews yet.